Polymer

To seal in hydrogen gas, rubber and resin materials are used in the hydrogen equipment that will support a hydrogen energy society. However, hydrogen seals such as O-rings face the possibility of breakage due to exposure to high-pressure hydrogen gas or increased and decreased pressure of hydrogen gas. The fracture modes of rubber O-rings when exposed to high-pressure hydrogen are shown below. The hydrogen that dissolved in the rubber caused blister fractures, overflow fractures and buckling fractures.

The Department of Polymers is studying the matter to clarify the fracture phenomenon affecting rubber and resin materials when they are exposed to high-pressure hydrogen environments. We investigate the dissolution behavior of hydrogen in materials by using thermal desorption spectroscopy and nuclear magnetic resonance methods to study its influence on the fracture behavior of materials. We are also examining the correlation between fracture behavior and usage environment, material structure and molecular structure, aiming at establishing development guidelines for hydrogen-resistant materials.

Fracture mode of the O-ring when sealing high-pressure hydrogen gas

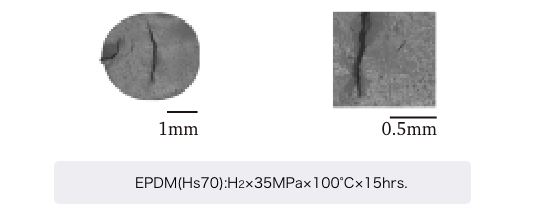

Blister fracture

Cause

Hydrogen that dissolves in rubber materials when they are exposed to high-pressure hydrogen environments vaporizes as the pressure is reduced, which generates bubbles and facilitates crack growth.

Countermeasure

(Countermeasures for O-ring rubber materials)

- Development of rubber compounds in which lower amounts of hydrogen dissolve

- Development of rubber compounds with greater hardness and fracture strength

- Carbon black, a filler, has a significant stiffening effect. But, due to hydrogen adsorption, the amount of hydrogen dissolved in rubber increases. Fillers with greater stiffening effects and lower hydrogen adsorption are being pursued.

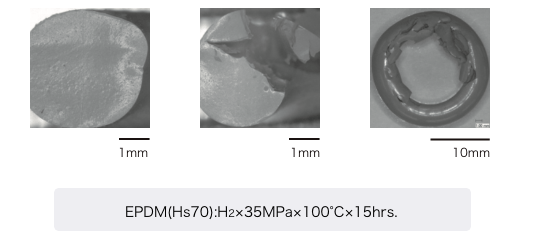

Overflow fracture

Cause

Due to hydrogen-induced swelling, the volume of the O-ring exceeds the cross-section of O-ring grooves, which are designed based on normal-state value, resulting in overflow fractures.

Countermeasure

(Countermeasures for O-ring rubber materials)

- Development of rubber compounds with lower rates of swelling-induced volume increase

- Pursuit of rubber materials in which lower amounts of hydrogen dissolve

(Countermeasures for the design of O-ring grooves)

- Filling rate design based on the premise that the volume of rubber materials will increase depending on usage environment (temperature, hydrogen pressure, etc.)

- Understanding of the limit values of the overflow and buckling fractures of rubber materials depending on usage environment (temperature, hydrogen pressure, etc.)

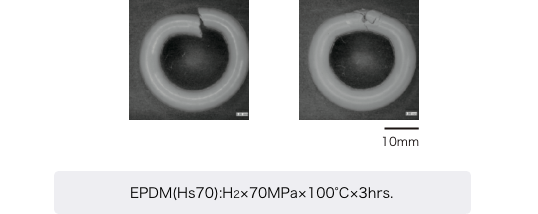

Buckling fracture

Cause

Due to hydrogen-caused swelling, the O-ring expands in the circumferential direction, leading to buckling fractures.

Countermeasure

(Countermeasures for O-ring rubber materials)

- Development of rubber compounds with lower rates of swelling-induced volume increase

- Pursuit of rubber materials in which lower amounts of hydrogen dissolve

(Countermeasures for the design of O-ring grooves)

- Filling rate design based on the premise that the volume of rubber materials will increase depending on usage environment (temperature, hydrogen pressure, etc.)

- Understanding of the limit values of the overflow and buckling fractures of rubber materials depending on usage environment (temperature, hydrogen pressure, etc.)

S. Nishimura

Outline of Activities

To seal in hydrogen gas, rubber and resin materials are used in the hydrogen equipment that will support a hydrogen energy society. However, hydrogen seals such as O-rings face the possibility of breakage due to exposure to high-pressure hydrogen gas or increased and decreased pressure of hydrogen gas.

The Department of Polymers is studying the matter to clarify the fracture phenomenon affecting rubber and resin materials when they are exposed to high-pressure hydrogen environments. We investigate the dissolution behavior of hydrogen in materials by using thermal desorption spectroscopy and nuclear magnetic resonance methods to study its influence on the fracture behavior of materials. We are also examining the correlation between fracture behavior and usage environment, material structure and molecular structure, aiming at establishing development guidelines for hydrogen-resistant materials.

Membership, etc.

- (General Incorporated Association) The Society of Rubber Science and Technology, Japan

- Director

- Kyushu Branch Manager

- Chief of the Research Group of Elastomer for Hydrogen Equipment

- ISO TC197/WG22

- Expert,Member of the Japanese Committee

- Japan Science and Technology Agency (JST)

- Regional Advisor for the Creation of Innovation Centers for Advanced Interdisciplinary Research Areas Program

- Ministry of the Environment (MOE)

- Committee to Review Green Community Demonstration Project including Waste Heat Utilization