Tribology

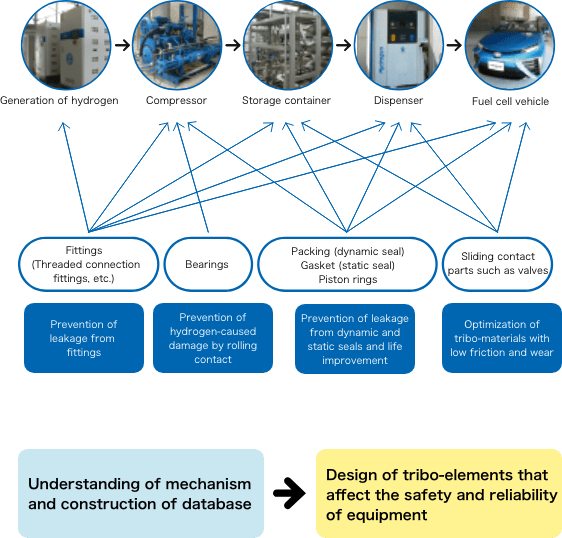

Many sliding contact parts, including bearings, valves, seals and fittings that are operable in hydrogen are used in fuel cell vehicles and hydrogen infrastructure equipment. Generally, various phenomena including friction and wear occurring on the surface of materials are influenced by atmospheric gas, and the coefficient of friction, wear amount, and rolling contact fatigue life in hydrogen gas environments are different from those in the atmosphere. Therefore, we need to accurately understand the tribology in hydrogen to secure the performance, life and reliability of the equipment in which hydrogen is used.

The Department of Tribology collects tribological characteristic data of various alloys, coatings, polymeric materials and rubber materials under normal and high-pressure hydrogen atmospheres to contribute to equipment development. We are studying the matter to clarify the changes in various processes that occur at the tribo-interface and the changes in the characteristics of the interface, as well as the dynamic change mechanism of the contact part, with an aim to establish a base of hydrogen tribology that can contribute to the reliability of mechanical systems using hydrogen energy in the future.

Elements of tribology in high-pressure hydrogen infrastructure

Y. Sawae

Outline of Activities

Comming Soon